INK PROPERTIES

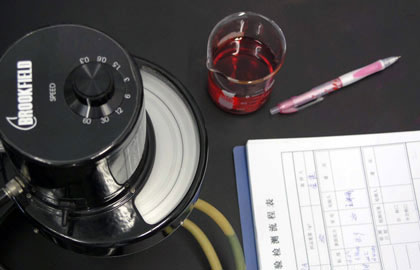

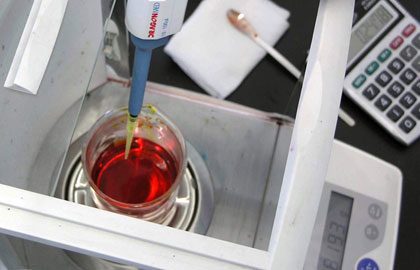

Viscosity

Viscosity is a measure of a liquid’s ability to resist flow. The viscosity of ink strongly affects printing stability, penetration and sharpness. Viscosity changes due to temperature so ink is recommended to use in a working environment of 15°C~35°C (59°F~95°F).

Conductivity

Conductivity shows the size of the ion concentration in the ink. Too much salt in the ink, the nozzle is easy to form crystals, resulting in damage to the cartridge. BCinks adopts salt filtration technology to produce stable ink with low salt inside.

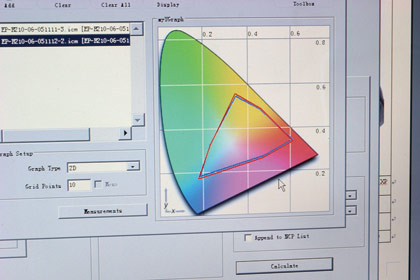

UV Spectrum

Ultraviolet-visible spectrophotometry refers to absorption spectroscopy or reflectance spectroscopy in the ultraviolet-visible spectral region. With this method we can analyze inks to do color matching, or to compare color density of inks with same raw materials.

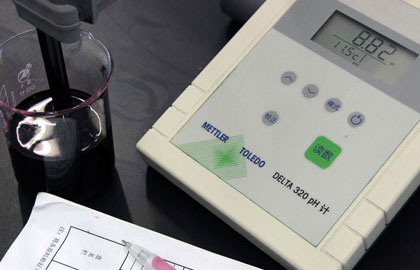

PH Value

Right pH range in the printing process must be maintained to avoid improper drying speed, foaming problem, etc. A running pH range should be established, and maintained. BCinks ink are generally in the weak alkali range in order to achieve the highest consistent printing quality.

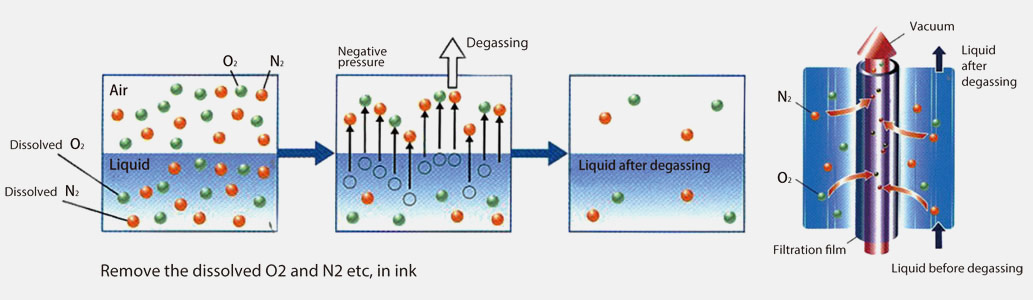

Particle Size

BCinks knows how to disperse pigment and maintain stability of pigment particles in ink production using our technology originated from Taiwan. With smaller particle sizes of 80nm -120nm(0.08-0.12um) for black and color inks, we can ensure consistent printing with no damage to the head and uniform absorption of the pigment molecules on the paper to present clear images in high resolution.

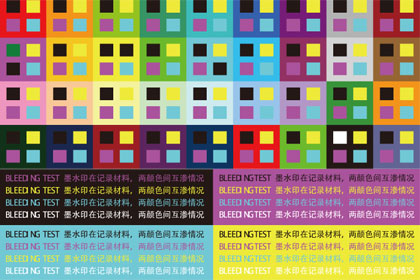

Surface Tension

Surface tension influences the dot stability, ink drying speed, bleeding and color performance on the print media.

Solvent based inks are naturally of lower surface tensions. Water based inks require surfactants to lower their surface tensions to acceptable levels for spreading and adhesion.

Different print heads would require different surface tensions, too. Ink formulations are made according to careful consideration of the above factors.